Niobium multigrade structural steels

They enable reduced inventories and investment capital, lower operational costs and much faster delivery times, improving the competitiveness of the sector.

Multigrade steels have more reliable properties, improving quality and productivity for fabricators and construction companies.

Niobium microalloying helps to reconcile the highest requirement of each steel, resulting in a very reliable product, with savings on production costs and the management of materials for the entire supply chain.

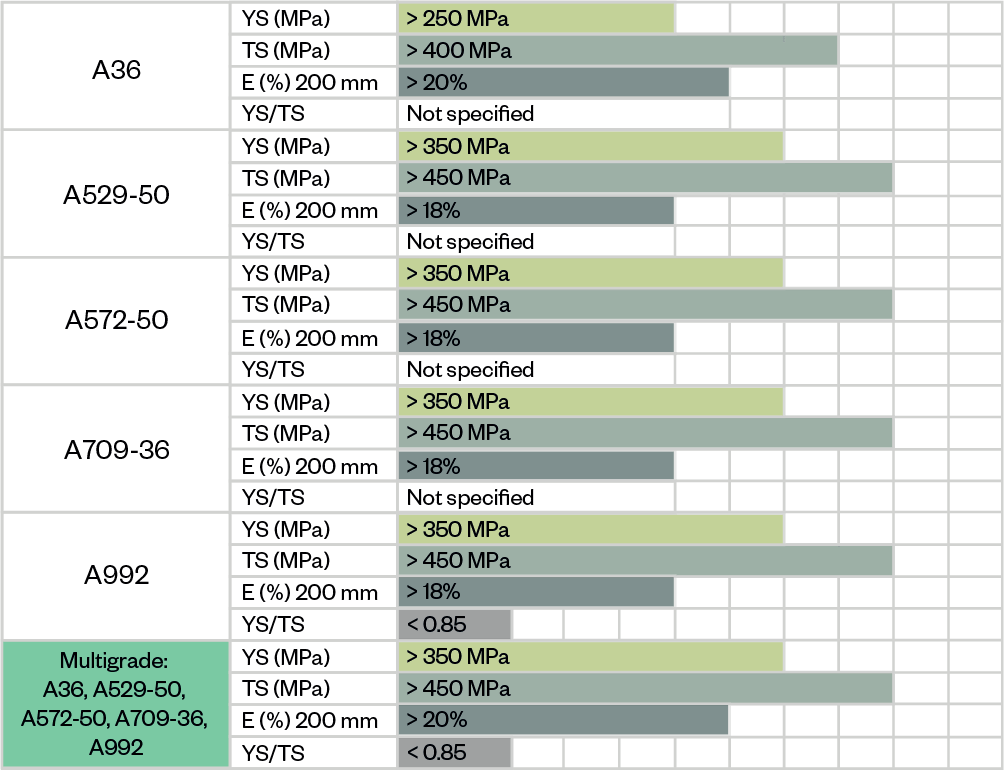

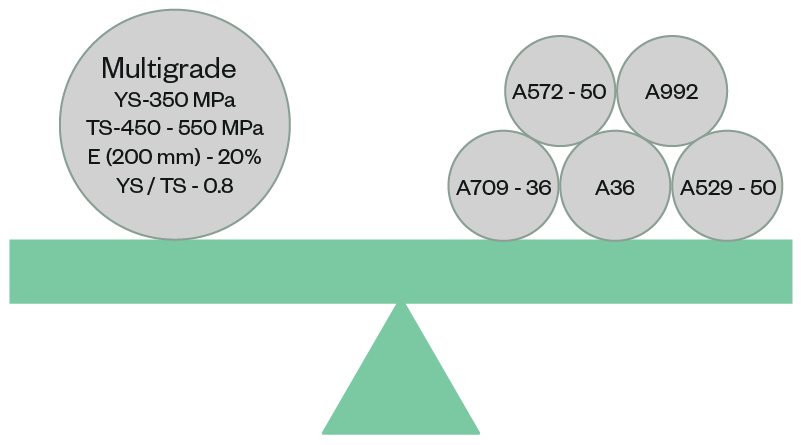

The table below shows how a multigrade steel can cover several specifications.

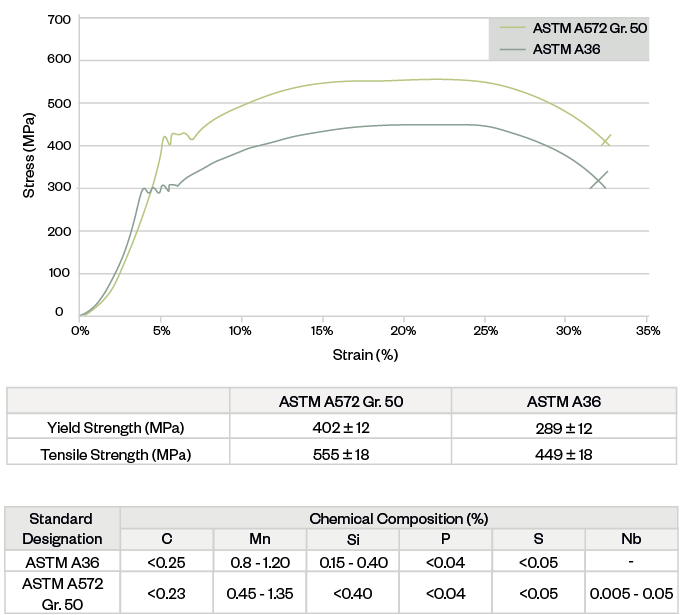

The figure below demonstrates how the use of niobium as a microalloying element can improve the strength of the material whilst also maintaining excellent ductility values.

Ibabe, J.M.R. – Development, Homologation and Dissemination for Extending Nb Application in Steel Processing, Flats and Long Products, D8 – Final Report , Internal report of CEIT, 2018.

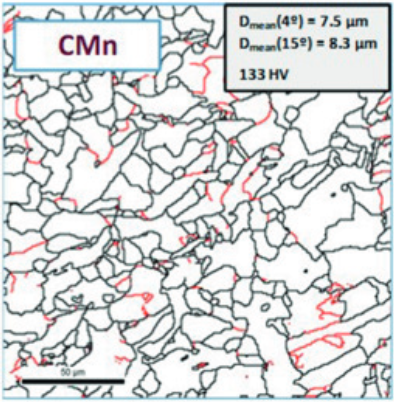

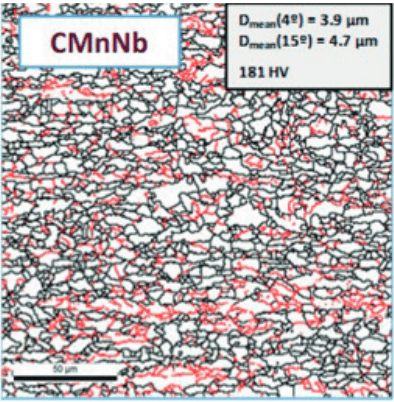

Grain refinement in rolled flat product by using 0.035%Nb. C-Mn (left) and C-Mn-0.035%Nb (right).

Even with niobium additions below 0.035%, these benefits can be demonstrated in multigrade steels, a major contributor to keeping costs competitive.

Therefore niobium microalloying is fundamental in the development of multigrade steels enabling a much more competitive supply in chain for structural steels.

Want to see this content in another format?

You may also like: